New Sunkid conveyor belt covers

Constant product development and revolutionary innovations are closely linked to the corporate culture of the Sunkid company from Imst in Tyrol. The revolutionary conveyor belts were developed by Sunkid as early as 1996 and have since been installed over 2,300 times worldwide. In close cooperation with its customers, the first conveyor belts were equipped with a canopy more than 8 years ago. The advantages are obvious - easier maintenance and operation of the system for the operator and protection from wind and weather for the guest. In the meantime, every fourth conveyor belt from Sunkid leaves the factory with a roof every year - more than 130 installations worldwide have already been roofed.

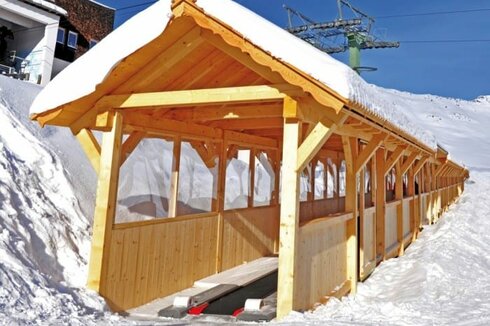

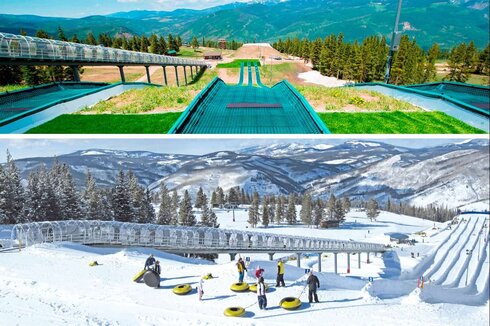

This year, Sunkid was able to install completely new types of roofing in very close cooperation with its customers. Based on the proven construction advantages of the previous Sunkid Gallery, impressive canopies were developed

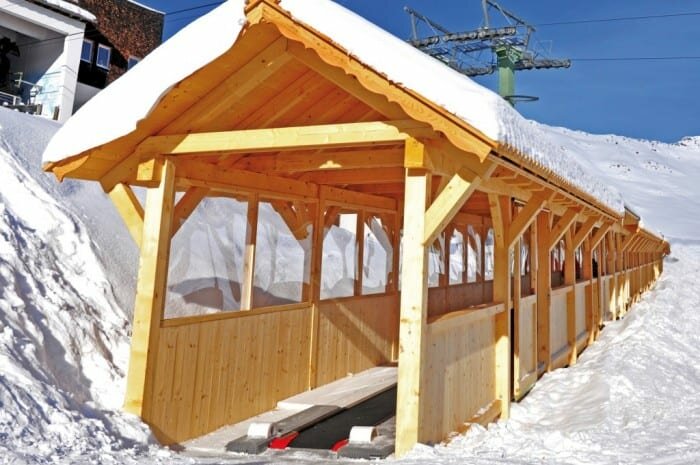

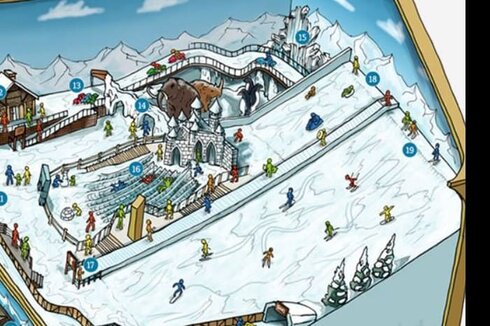

The world-famous "Kinderschneealm" in Serfaus celebrates its 20th anniversary this year. This year, the Komperdell Cable Cars, the Serfaus Ski School and the Serfaus Tourism Association have developed a comprehensive concept for the redesign of the 45,000 m² area. A spatial separation of the assembly areas facilitates orientation and with the new, cozy "Murmlihütte" the Kinderschneealm - located directly in the ski area below the Komperdell middle station - lives up to its name. The new family downhill run "Bärenpiste" leads over playful obstacles made of wood directly to the Kinderschneealm and the new bear meeting point.

The main connection from the Kinderschneealm to the gondola lift and the restaurant is a 70-meter Moving Carpet by Sunkid. This installation can transport guests both downhill and uphill (i.e. in both directions). Sunkid was given the task by the customer of equipping this main artery, which is used all year round, with a canopy that would visually fit into the overall concept of the new Kinderschneealm. So Sunkid, together with its partner Almholz, developed a wooden gallery modeled on a Tyrolean stable. A particular challenge here was two cable cars that cross just above the gallery. An appropriate safety concept was developed in close cooperation with the Tyrolean provincial government. The conveyor belt and wooden gallery were approved by the authorities at the beginning of December without any problems. As a result, 14 Sunkid conveyor belts have been in operation in Serfaus since this year, half of which are covered.

The basic idea of the Sunkid Gallery Varios is the flexible combination of different materials. A solid, fully galvanized metal substructure supports wooden glulam elements with polycarbonate panels, which are easily and quickly screwed together on site. The main focus in the development of this gallery was not only the visual appearance, but also the simple and space-saving storage possibility of the elements (transport or storage in summer), the adaptability to all terrain shapes without any cutting/adjustment on site as well as the simple and easy assembly/disassembly. The Varios gallery is thus built in the proven modular construction method; the heaviest part weighs 70 kg and can thus be moved by 2 people.

Individually designable claddings made of various materials and shapes (e.g. larch shingles, wooden strips of all kinds, stone slate panels, ornaments, glass panels, checker plate, backlit pictures, prints of any kind and shape) in the lower area offer a variety of design options and provide the individual touch.

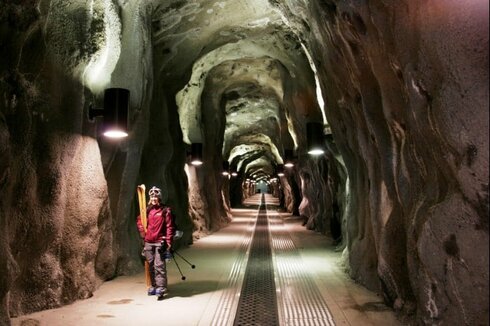

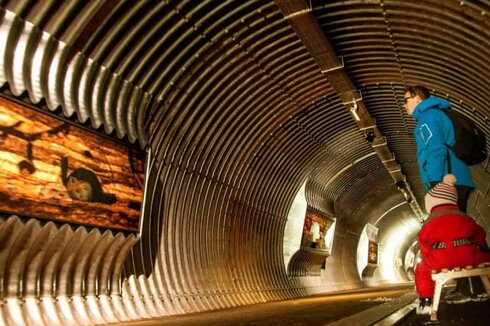

The Sunkid development department thus constructed a "Duplex" gallery with an interior passage width of 330cm and an interior height of 250cm. Also in this gallery, different materials were combined with each other. The basis is again a solid fully galvanized metal substructure. New aluminum profile half arches form the basic structure of the roofing. The entire upper area is filled with 5mm thick polycarbonate panels. In the lower area, impregnated wooden boarding provides a soft and pleasant feeling of space. Electric rolling gates are installed at the entrance and exit. Every 15m there are side openings that can be closed with sliding doors.