A connecting lift adorned with the latest technical innovations

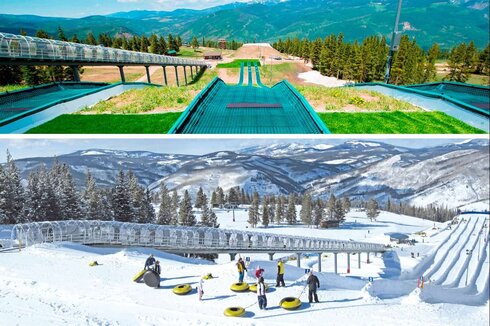

The Moving Carpet hasa very wide range of applications and can be found in many areas of a ski resort. Whether in the beginner's area, as a connecting belt from the parking lot to the valley station, as a feeder to the gastronomy, as a connection to the village center or the public transport. Wherever differences in altitude, obstacles or inclines need to be bridged, the Moving Carpet has established itself as the ideal means of transport. Especially when it comes to connecting routes, however, these are often used not only by winter sports enthusiasts, but also by pedestrians. And at this point at the latest, the Sunkid Moving Carpet finally plays its trump card against other means of transport.

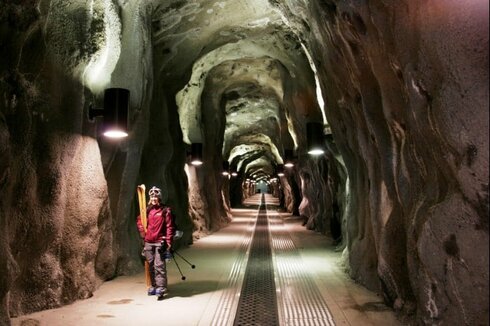

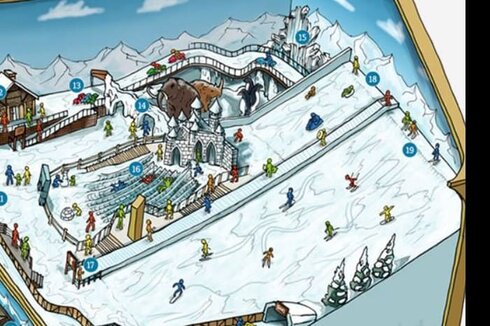

The new glacier lift on the Rettenbachferner in Sölden was also designed and implemented as a connecting lift. Due to the recession of the glacier, the old connecting path between the two ski slopes "Seiterjöchl" and "Rettenbachjoch/Schwarze Scheid 1 (World Cup slope)" can no longer be used. The slope was therefore lengthened on the downhill side, thus bypassing the affected area. However, this means that skiers can no longer return directly to the "Gletscherexpress" and "Schwarze Schneide" lifts. A height difference of 17m separates them.

To bridge this height difference, the Ötztal Gletscherbahnen tested various logistics solutions and finally decided on a 174m long Moving Carpet as a connecting conveyor.

The new conveyor belt is adorned with numerous technical innovations.

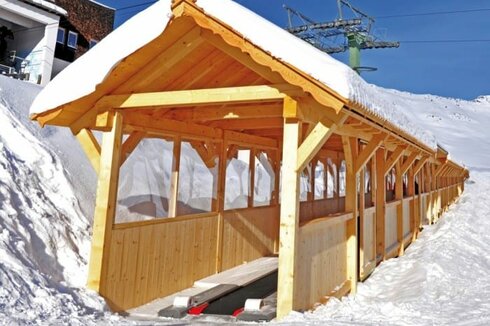

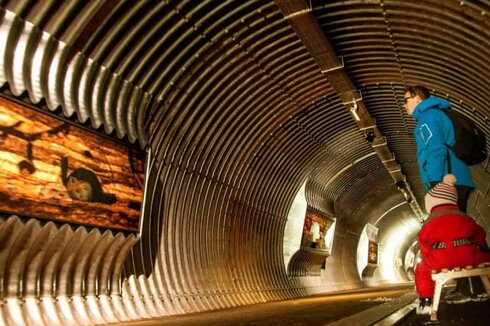

In order to meet the customer's specification of a practical (not theoretical) conveying capacity of 1,800 people per hour despite a considerable sag in the middle of the installation, a drive power of 37 kW was chosen. A Counterweight Tensioning system with a tensioning travel of 2.8m and a tensioning weight of 2 tons ensures optimum belt tension with minimal maintenance. The proven Blue Eye conveyor belt with a belt width of 900mm gives the passengers perfect hold even on inclines of up to 18%. The conveyor belt was designed with a strength of 500 N/mm with 4 tensile layers and vulcanized on site. The system runs at a maximum speed of 1.2 m/sec which is infinitely variable and is equipped with the proven Sunkid safety switch flap at the belt infeed. The Evolus gallery roof ensures low-maintenance daily operation even at an altitude of 2,680m and protects passengers from wind and weather. Entrances and exits are easily closed with electric rolling gates at the push of a button. Every 18m there are emergency exit passages which can be locked with high quality sliding doors.

The installation has been designed for maximum wind speeds of 165 km/h and has been secured on both sides with special rattle anchors every 2m.

The turbine was also equipped with the new i-CONTROL® electrical control system. This new control system was already intensively tested on several lifts in the winter of 2020/21 and has been used by Sunkid as standard on all lifts in the Alpine region since this winter.

The key features of the i-CONTROL®:

- Multi-touch HMI with all relevant information for operation, maintenance and troubleshooting.

- Including 4 different password-protected user groups, each with a defined release of functions.

- Including digital maintenance plan of the plant

- Remote access to the electrical control via internet for customer and manufacturer (for extended customer support).

- Regular reports by e-mail on the most important operating data (such as utilization, etc.) to various recipients (customer or manufacturer)

The operation of the plant can be done from different locations according to the customer's wishes. Either directly at the plant in the entry or exit area or at the monitoring point of the own locksmith's shop, which is about 150m away. Appropriate camera monitoring and remote control equipment was installed for this purpose.

The system was tested and positively accepted by the responsible authority of the Tyrolean provincial government according to EN15700.

Operations Manager of Ötztaler Gletscherbahnen - Markus Arnold: ,,In view of the extreme weather conditions, we have trimmed the system for the most trouble-free operation possible and a quick start-up after precipitation. In October, 60,000 guests used the comfortable lift, with daily peaks of up to 6,400 rides. No surface lift has these frequencies. Use of the conveyor belt is possible with skis and snowboard on your feet as well as in pedestrian style."

Gallery: Evolus XL