The largest and highest Ferris wheel in the world

Access to the cabins is via a loading conveyor and access gates from Sunkid.

Ain Dubai is now the largest and highest Observation wheel in the world at over 250 meters. The observation wheel thus trumps the High Roller in Las Vegas (168 meters), the Singapore Flyer (165 meters), or the London Eye (135 meters).

The observation wheel is surrounded by 48 luxuriously equipped passenger cabins, which can carry around 1,750 visitors at a time.

Challenging project

Construction of the Ferris wheel began back in 2015 and more than 10 countries around the world were involved - including Sunkid with its Moving Carpet. For Sunkid, this project meant an enormous project effort, which was technically handled by Bruckschlögl GmbH in Bad Goisern. Thus, in addition to the development work and production, over 2,000 hours were invested in planning and project management.

The first complete assembly for the acceptance by TÜV Süd could still be completed in the assembly hall in Austria. For the final assembly in Dubai, the night hours also had to be used. Although this meant that the most extreme temperatures could be avoided in late summer, the assembly team was nevertheless challenged to the utmost due to temperatures beyond 35°C, high humidity and cramped conditions.

After Covid-related delays in the overall project, the facility, including the loading conveyor and access gates, gained official acceptance in the summer of 2021, with the official opening taking place on October 21, 2021.

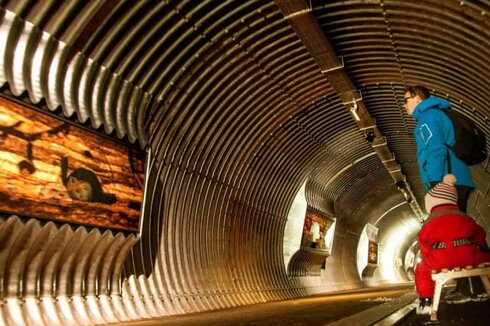

higher capacity and safety thanks to loading conveyor and access gates

The conveyor belts from Sunkid - originally developed as ski conveyor belts and proven there thousands of times in passenger transportation - convince again and again with new functions and technologies and open up new applications.

This is also the case at Ain Dubai: Both the access gates and the loading conveyor from Sunkid are used to enter the passenger cabins.

As the observation wheel rotates continuously, the loading conveyor ensures that the speed difference between the moving gondolas and the static platform is optimally matched to the required safety and maximum achievable capacity. Sunkid's loading conveyor allows the Observation Wheel to travel up to 30% faster and therefore provide 30% more capacity per hour. In addition, the loading conveyor is also designed to be part of the evacuation route in case of emergencies.

SUNKID THE MASTER FOR SPECIAL REQUIREMENTS

In this project, additional very special requirements had to be met, which are briefly summarized again here:

- Special U-shape (concave) of the "rolling moving walk," which thus follows the special shape of the platform

- Special link chain design for safety, quiet operation and slip resistance

- Link chain with color markings so that edges and direction of movement can be easily detected by passengers

- Antistatic design of link chain

- Special cleaning function to suit local climatic conditions (heat, dust, wind, sea)

- Special chain tension to eliminate vibrations

- Independent control of the loading conveyor communicates with the control of the Ferris wheel and the access gates.

INTERESTING FACTS

- Sunkid develops and builds all its conveyor belts 100% at the Bruckschlögl GmbH site in Austria. Not only the Moving Carpet for ski applications comes from there, but also conveyor belts for transporting people or tubes in water parks or white water facilities.

- Ayn', Ain - is the 16th letter of the Arabic alphabet and translates as 'eye'.

- Each individual spoke of the 'Wheel' is longer than a soccer field

- A single cabin is larger than two double-decker buses side by side

- A total of approx. 11,200 tons of steel are installed

- A complete rotation takes about 38 minutes

technical data loading conveyor:

- Width: approx. 1.6m

- length: approx. 44 m

- Capacity Observation wheel: up to 1750 people at the same time

- Speed: adapted to the rotation speed of the Observation Wheel. Normal speed 0.2 m/s. Deceleration at emergency stop 0.15 m/s².

- Requirements: built according to the conveyor standard EN 15700